How Does a Heat Exchanger Work?

A heat exchanger is a crucial component in many industrial and residential systems, designed to efficiently transfer heat between two or more fluids without direct contact. Whether used in HVAC systems, refrigeration, or manufacturing, these devices play a key role in energy efficiency and temperature control. GroupMCD specializes in providing expert solutions, including plate heat exchanger maintenance teams to ensure optimal performance and longevity.

The Basics of Heat Exchange

Heat exchangers operate on the principle of thermal energy transfer. They allow heat to pass from a hot fluid to a cooler one through a solid barrier, preventing the two fluids from mixing. This process is fundamental in applications such as cooling systems, heating units, and industrial processing. Heat exchangers enhance energy efficiency by optimizing heat reuse, reducing overall operational costs, and minimizing environmental impact.

Types of Heat Exchangers

- Plate Heat Exchangers – Consisting of multiple metal plates stacked together, these exchangers maximize surface area for efficient heat transfer. They are commonly used in food processing, pharmaceuticals, and HVAC systems.

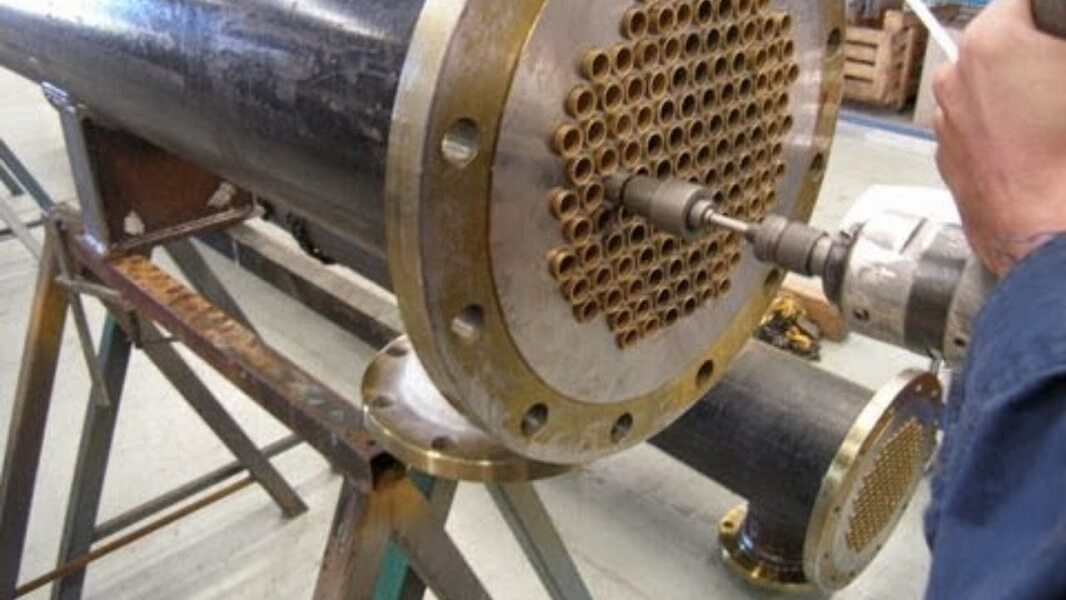

- Shell and Tube Heat Exchangers – This type features a bundle of tubes enclosed within a cylindrical shell. Fluids flow through the tubes and around the shell to facilitate heat exchange, ideal for large-scale industrial applications.

- Air-Cooled Heat Exchangers – Used where water is scarce, these exchangers rely on air flow to dissipate heat, making them suitable for power plants and automotive cooling systems.

How Plate Heat Exchangers Work

Plate heat exchangers function by allowing fluids to flow through alternating channels between metal plates. The high surface area and turbulent flow enhance heat transfer efficiency. These exchangers are compact, easy to maintain, and highly efficient compared to traditional models. Their modular design allows for easy expansion or modification, making them a flexible solution for various industries.

Importance of Regular Maintenance

Ensuring optimal performance requires routine maintenance. Over time, contaminants, scaling, and fouling can reduce efficiency. Plate heat exchanger maintenance teams conduct inspections, cleaning, and part replacements to prevent costly breakdowns. Routine maintenance includes descaling, gasket replacement, and leak detection, which ensures continued high performance and extends equipment lifespan. Regular maintenance helps improve energy efficiency and lowers operational costs by preventing unnecessary repairs and downtime.

Applications of Heat Exchangers

- HVAC Systems – Regulating indoor temperatures efficiently to provide comfort and energy savings.

- Refrigeration – Removing heat to maintain low temperatures in food storage and preservation.

- Industrial Processing – Managing heat in chemical, food, and pharmaceutical industries to ensure proper temperature control during production.

- Power Generation – Enhancing turbine and generator efficiency by recovering waste heat.

- Automotive Industry – Maintaining optimal engine temperatures to prevent overheating and improve fuel efficiency.

- Oil and Gas Industry – Used in refining and processing to regulate fluid temperatures.

Key Benefits of Heat Exchangers

- Energy Efficiency – Reduces energy consumption by transferring and reusing heat.

- Cost Savings – Minimizes operational costs by lowering the need for additional heating and cooling sources.

- Environmental Benefits – Reduces emissions by improving overall energy efficiency.

- Versatility – Used in a wide range of industries, making them a valuable investment.

- Durability – When properly maintained, heat exchangers offer long-term reliability and performance.

Conclusion

Heat exchangers are essential in various industries, ensuring efficient temperature regulation and energy conservation. Investing in professional maintenance, such as services provided by GroupMCD, guarantees reliable operation and extended equipment lifespan. Proper care and timely servicing of plate heat exchangers significantly impact performance and cost savings in the long run.