The Future of Hygiene Product Manufacturing: Advanced Sanitary Napkin & Diaper Production Machines

In today’s fast-paced world, the demand for hygiene products such as sanitary napkins and diapers is constantly growing. To meet this demand, manufacturers need efficient and high-quality production solutions. This is where advanced sanitary napkin production lines and diaper production lines come into play. These automated systems are designed to increase efficiency, reduce labor costs, and ensure consistent product quality.

Read Also: Diaper machine manufacturer

Cutting-Edge Sanitary Napkin Production Line

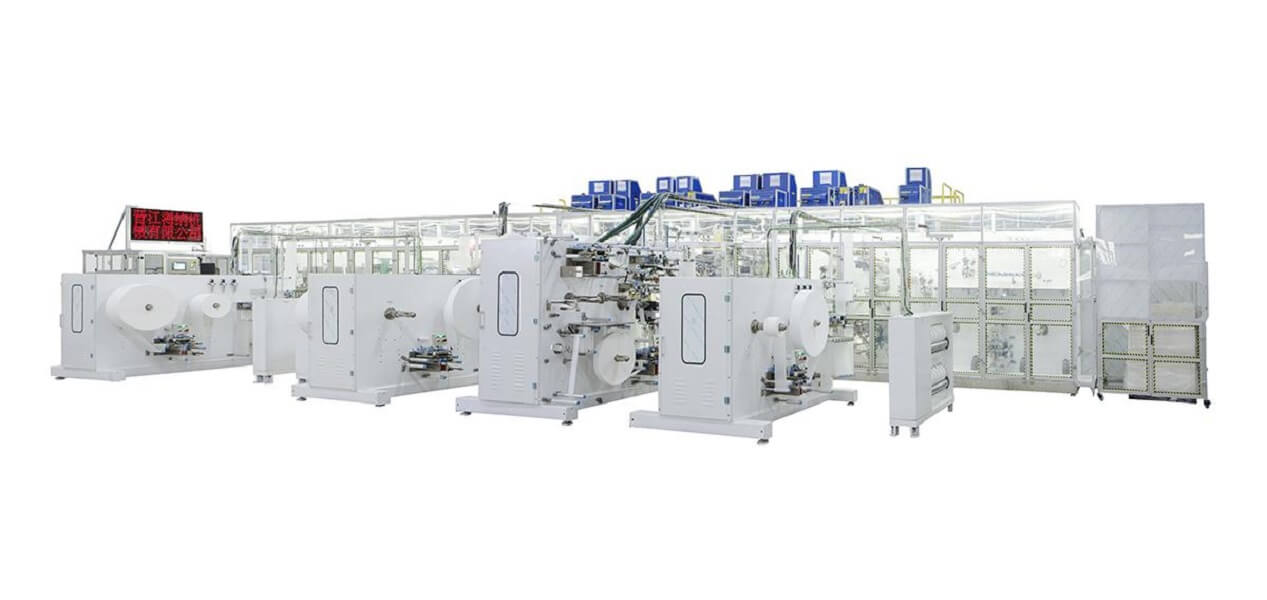

A sanitary napkin production line is a fully automated system that manufactures sanitary pads from raw materials, ensuring precision in size, absorbency, and packaging. These machines are equipped with the latest technology to handle various types of sanitary napkins, including ultra-thin, maxi, and organic cotton pads.

Features of an Automatic Sanitary Napkin Machine:

- High-Speed Production: Capable of producing thousands of sanitary napkins per hour.

- Customizable Sizes & Absorbency Levels: Allows manufacturers to create different variants based on market demand.

- Efficient Packaging System: Ensures each napkin is properly sealed and hygienically packed.

- Waste Reduction Technology: Minimizes material waste, making production more eco-friendly.

With the latest automatic sanitary napkin machine, manufacturers can enhance their productivity and ensure the highest quality of hygiene products for consumers.

The Importance of an Advanced Diaper Production Line

A diaper production line plays a crucial role in the manufacturing of both baby and adult diapers. These machines are designed to meet the growing market needs while maintaining efficiency, accuracy, and hygiene standards.

Key Benefits of a Diaper Machine Manufacturer’s Technology:

- Automated Process: Reduces manual intervention, ensuring faster production and improved hygiene.

- Multi-Layer Absorption Technology: Enhances leak protection for maximum comfort.

- High-Speed Output: Modern diaper machines can produce thousands of units per day.

- Versatility: Supports the production of both baby diapers and adult diapers, catering to a wide consumer base.

- Energy-Efficient Operations: Optimized to use minimal power while maintaining high efficiency.

By partnering with a trusted diaper machine manufacturer, businesses can ensure the production of high-quality, cost-effective, and durable diapers that meet market standards.

Why Choose Automated Hygiene Product Machines?

The automation of sanitary napkin pad making machines and diaper production lines has transformed the hygiene product industry. Here are some of the key reasons why manufacturers are increasingly adopting these technologies:

1. Improved Productivity & Efficiency

Automated machines are capable of working around the clock, significantly increasing output and reducing production time.

2. Consistent Quality & Hygiene

These machines ensure that every product meets strict hygiene and quality standards, reducing defects and inconsistencies.

3. Cost-Effective Solutions

While the initial investment in an automatic sanitary napkin machine or diaper machine may seem high, the long-term savings on labor and material waste make it a worthwhile investment.

4. Sustainability & Eco-Friendly Production

Many modern sanitary napkin production lines and diaper production lines use biodegradable and recyclable materials, reducing environmental impact.

Choosing the Right Manufacturer

When selecting a diaper machine manufacturer or a sanitary napkin machine provider, it is essential to consider factors such as:

- Reputation & Experience: Choose a manufacturer with a strong track record in hygiene product machinery.

- Customization Options: Ensure that the machines can be tailored to specific production needs.

- After-Sales Support & Training: A reliable manufacturer should offer technical support and operator training.

Final Thoughts

The demand for sanitary napkins and diapers is only set to grow, making it crucial for manufacturers to invest in cutting-edge sanitary napkin production lines and diaper production lines. With the right automatic sanitary napkin machine and diaper machine manufacturer, businesses can achieve higher efficiency, product consistency, and sustainable production.

For those looking to scale their hygiene product manufacturing, automated solutions are the key to success.