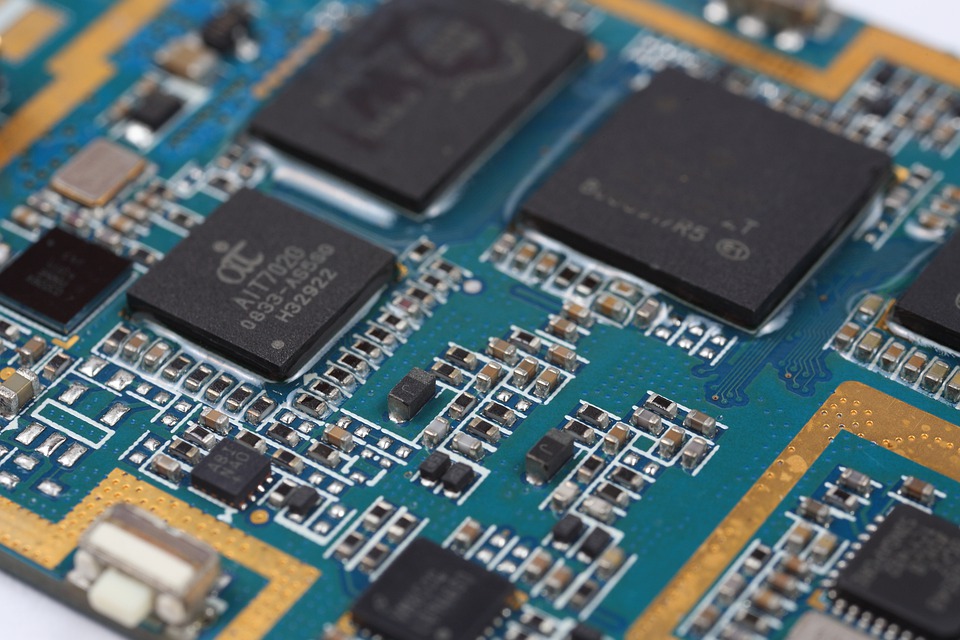

PCB Manufacturing Process

The PCB manufacturing process is very essential for anyone working in the electronics industry. Printed circuit boards, PCBs, are very broadly used as the basis for electronic circuits.

Accordingly, virtually all circuits use printed circuit boards and are designed and used by millions.

Although printed circuit boards are the backbone of almost all electronic circuits today, they are generally taken for granted. However, technology in this area of electronics is advancing.

The manufacturing process for a printed circuit board can be carried out in many different ways, and there are several options. Despite many small variations, the basic steps in the PCB manufacturing process are the same.

PCB constituents

Printed circuit board PCB UK, can be made from various materials. The most widely used fiberglass board is known as FR4. This provides a reasonable degree of stability over temperature fluctuations, and it does not break much, but it is not prohibitively expensive.

To make a PCB with component tracks, you first get a copper-plated PCB. It consists of a backing material, FR4, with copper cladding usually on both sides. This copper cladding consists of a thin layer of the copper sheet attached to the board. This connection is usually very good for FR4, but the very nature of PTFE makes it more difficult, and it adds complexity when handling PTFE PCBs.

The Basic PCB Manufacturing Process

Once bare PCBs are selected and available, the next step is to create the required traces on the board and remove unwanted copper. The manufacture of printed circuit boards is usually carried out using a chemical etching process. The most common form of PCB etching is ferric chloride.

A photographic process is used to obtain the correct pattern of the tracks. Typically, copper on bare PCBs is coated with a thin layer of photoresist. He is then exposed to light through film or a photo mask detailing the required tracks. Thus, the image of the tracks is transferred to the photoresist. In this kit, the photoresist is placed in the developer so that only those areas of the board where the tracks are needed are covered with the resist.

The definition of Flex PCB manufacturer is to get their name for their ability to design a circuit that fits an electronic device or product, as opposed to creating a device that fits a printed circuit board. Flex boards feature a distinctive printed circuit design and component layout, accentuated by a pliable base material. The next step in the process is to place the PCBs in ferric chloride to etch areas where no trace of copper is required. Knowing the concentration of ferric chloride and the thickness of copper on the board, it is placed in the etching foam for the required time. If the PCBs are etched for too long, some legibility is lost as the ferric chloride will tend to undercut the photoresist.